Rubber compression stress relaxation Tester distribution|stress relaxation testing : importers Compression stress relaxation (CSR) testing: considerations in an era Of ISO 17025 proficiency testing. Paul Tuckner, Grace Technology & Development. In looking at elastomer testing in general and CSR testing in .

WEB4 de set. de 2023 · Renata Miguel da Silva, de 15 anos, com a mãe Angelita Imagem: Arquivo Pessoal. Angelita Miguel da Silva, de 45 anos, nunca imaginou que deixar a .

{plog:ftitle_list}

Preço. Qualidade. Duosat Troy HD Legacy. Os melhores Receptores via Satélite, Cabo ou IPTV da Duosat.

ISO 6914 describes the testing of stress relaxation in tension. This can be done by two methods, either on continuously stretched samples or intermittent stretched samples. The test .Reducing of stresses in rubber – stress relaxation is a joint expression of the elastic and viscous properties of the material. We apply the generalized Maxwell model or it has another .

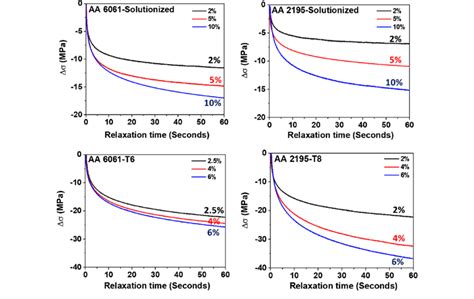

Stress relaxation testing provides a measure of the viscoelastic response of a material over a period of time without destroying the structure of the sample. In such testing both the . A decrease in force response with time of rubber can be experimentally evaluated by the stress relaxation test. In the present work, the localized stress of vulcanized rubber . In the present work, the localized stress of vulcanized rubber during a compressive stress relaxation test (i.e., ASTM D6147) was evaluated. Hyperelastic behavior was assumed during rapid application of strain, while . Compression stress relaxation (CSR) testing: considerations in an era Of ISO 17025 proficiency testing. Paul Tuckner, Grace Technology & Development. In looking at elastomer testing in general and CSR testing in .

stress relaxation testing

stress relaxation parameters

Compression Stress Relaxation (CSR) continues to be an important attribute in the evaluation of materials and seal configurations for their ability to provide sealing force .

Molecular weight distribution influ-ences viscosity and elasticity of raw natural rubber and dif-ferent impurities in raw NR influence the rubber hydrocar-bon stability in processing and .This document specifies two procedures for determining the decrease in counterforce exerted by a test piece of vulcanized or thermoplastic rubber which has been compressed to a constant .

stress relaxation lab study

Correlation Between Compression-Set and Compression Stress-Relaxation of Epichlorohydrin Elastomers ©SmithersRapraTechnology,2011 1. INTRODUCTION Compression stress-relaxation is considered to be the most direct measure of the sealing capacity of an elastomer. It gives the force a rubber article would exert on a solid Experience with compression stress relaxation measurement was not particularly widespread when the ISO standard was first formulated, a variety of apparatus was in use and reproducibility was not good. . Test methods for rubber ‘O’ rings. Google Scholar ASTM F36, 2015. Compressibility and recovery of gasket material. Google Scholar ASTM . Rubber stress relaxation models are the main material input data for numerical and analytical conveyor belt indentation rolling resistance calculations. Stress relaxation data for rubbers, such as those used in the construction of conveyor belts, are difficult to measure directly due to their fast relaxation times and, as such, they are usually derived via a dynamic . Therefore, the current continuous compression stress relaxation (CCSR) test aims to offer an improved method of evaluating rubber compounds. ARDL Continuous Compression Stress Relaxation Test. The ARDL CCSR apparatus is shown in Figure 1a and Figure 1b. It consists of 5 fixtures placed inside a temperature chamber.

stress relaxation lab report

the commencement of that time-interval. (Stress relaxation is a synonym.) 4. Summary of Test Method 4.1 Method AÑThe test specimen is compressed at the test temperature, and it is maintained at this temperature through-out the test period, all force measurements being made at the test temperature. 4.2 Method BÑThe test specimen .Rubber, vulcanized or thermoplastic — Determination of stress relaxation in compression — Part 1: Testing at constant temperaturebut decreases with time; this behaviour is called “stress relaxation”. Conversely, when rubber is subjected to a constant stress, an increase in the deformation takes place with time; this behaviour is called “creep”. Tests in compression are normally made under continuous stress conditions (i.e. the test piece remainsOur rubber and plastic testing experts have years of experience conducting accelerated aging testing to industry standards and custom specifications. Common Standards for Stress Relaxation Testing. ASTM D6147—Standard Test Method for Vulcanized Rubber and Thermoplastic Elastomer—Determination of Force Decay (Stress Relaxation) in Compression

Compression stress relaxation (CSR) testing: considerations in an era Of ISO 17025 proficiency testing January 26, 2021 April 12, 2021 RubberWorld 3792 Views. Paul Tuckner, Grace Technology & Development. . and has been the primary driver for many of the requirements in rubber testing. Many of the test requirements created for this market .Rubber, vulcanized or thermoplastic - Determination of stress relaxation in compression - Part 1: Testing at constant temperature This document specifies two procedures for determining the decrease in counterforce exerted by a test piece of vulcanized or thermoplastic rubber which has been compressed to a constant deformation and maintained .The Compressive Stress Relaxation Test (DIN) ISO 3384-1 describes two methods for determining stress relaxation under pressure. In addition, the American SAE J 2979 also defines tests for compressive stress relaxation. An elastomer specimen is compressed with a constant load and the force it exerts against this external influence is measured.

The findings can give the localized phenomena of vulcanized rubber during a stress relaxation test, which can be used as a guideline for the design, usage, and improvement of rubber and viscoelastic polymeric components. . In each level of compression, the stress relaxation tests were repeated 3 times, and their average was used for the .Compression set 2 Instruments . While Mooney testing does not provide sufficient information to clearly differentiate branching and Molecular weight distribution the Rubber Process Analyzer can easily be used as a tool for solving production problems. . Stress Relaxation. As Mooney Viscosity testing only provides information about the flow .

stress relaxation experiment

The specimens of silicone rubber materials were immersed in the air, in the DI water, in the RS and in the ADT environments at temperatures of 30, 70, and 90°C, individually. Then the exposed samples were detached for compression set test and stress relaxation test at 25% strain levels individually at room temperature for every selected time.

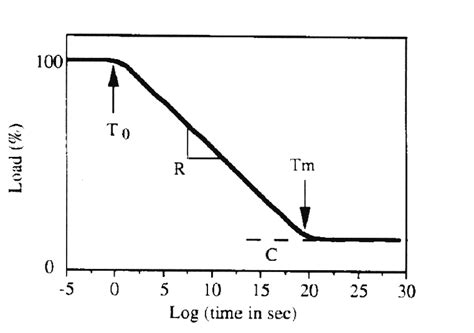

hand refractometer procedure

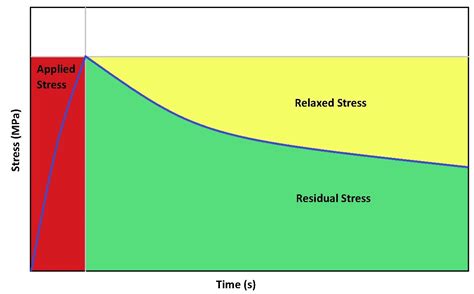

given time during a stress relaxation test. 3.1.5 relaxed stress—the initial stress minus the remaining stress at a given time during a stress relaxation test. 3.1.6 stress relaxation curve—a plot of the remaining or relaxed stress as a function of time. 3.1.6.1 Discussion—A curve to demonstrate that the stress relaxation behavior can be .are recorded. The stress relaxation of rubber can usually be described through power law model M = k (t)a (1) where: M = torque units from the Mooney stress relaxation test, k = a constant equal to torque 1 s after the rotor has stopped, and a = an exponent that measures the rate of stress relaxation. The Eq.

Compression Stress Relaxation (CSR) continues to be an important attribute in the evaluation of materials and seal configurations for their ability to provide sealing force retention under a range of conditions. . Citation: Tuckner, P., "Compression Stress Relaxation Testing - Comparisons, Methods, and Correlations," SAE Technical Paper 2001 .

hand refractometer range

Creep Test The creep test, also known as the stress relaxation test, is a destructive way of evaluating a material’s durability and thermal stability. . Compression stress relaxation testing on vulcanized and thermoplastic rubber; Video 01: Creep Test. Start Material Testing.were detached for compression set test and stress relaxation test at 25% strain levels individually at room temperature for every selected time. The test procedure follows the GB/T 7759.1-2015 and GB/T 1685-2008 standards. The data obtained in this study may be used to investigate the effect of different operating conditions, acids,molecular weight distribution – natural rubber 200 – synthetic raw rubber 205 Monsanto Processability Tester (MPT) 55 . RPA stress relaxation 281 Practical Rubber Rheology and Dynamic Properties downloaded from www.hanser-elibrary.com by 20.79.107.247 on October 27, 2024 . stress relaxation test 120, 169 S′ value 82 S″ value 82 .

(1.) ASTM D 395, Standard Test Method for Rubber Property--Compression Set, Method B, Compression Set Under Constant Deflection in Air. (2.) ASTM D 6147, Test Method for Vulcanized Rubber and Thermoplastic Elastomer--Determination of Force Decay (Stress Relaxation) in Compression. (3.)

The extracellular matrix and most tissues are stress relaxing, and the kinetics of stress relaxation have been recognized as an important mechanical cue that affects the migration, proliferation, and differentiation of embedded cells. [2] Stress relaxation calculations can differ for different materials: To generalize, Obukhov uses power . Considering the different stress relaxation mechanisms reported in the literature (Abu-Abdeen, 2010, Mohammad and Mohammadian-Gezaz, 2011, Maria et al., 2014), the stress relaxation observed in the first few seconds of the test (pair A 1 and τ 1) occurred mainly due to the rupture of highly stressed rubber chains (rubber matrix contribution . 5.1 When a constant strain is imposed on rubber, the force necessary to maintain that strain is not constant but decreases with time; this phenomenon is called force decay (stress relaxation). Conversely, when rubber is subjected to a constant stress, an increase in the deformation takes place in time; this behavior is called creep.the mechanical behavior of stress relaxation. The results of stress relaxation will cause the attenuation of surface con-tact stress, which will have a direct negative impact on the waterproof capacity of the tunnel, and make it dicult to meet the design goal .

given time during a stress-relaxation test. 3.2.4 spherometer, n—an instrument used to measure circu-lar or spherical curvature. 3.2.5 stress-relaxation curve, n—a plot of either the remain-ing time or relaxed stress as a function of time. 3.2.6 stress-relaxation rate [FL−2 T–1],n—the absolute value of the slope of the stress . Specifying Conditions for Compression Stress Relaxation Testing of Rubber and Thermoplastic Elastomers 90A or Less active, Most Current Buy Now. Details. History . Specifying Conditions for Compression Stress Relaxation Testing of Rubber and Thermoplastic Elastomers 90A or Less Introduction Note: Nothing in this standard supercedes .

hand refractometer reading

hand refractometer scale

A letra menciona o respeito pelo juiz e pelo patrão, indicando a hierarquia e a disciplina presentes no ambiente da vaquejada. A canção de Tarcísio do Acordeon é um retrato .

Rubber compression stress relaxation Tester distribution|stress relaxation testing